Thirst Snowboards

Un altra piacevole scoperta per gli appasionati dello snowboard alpino

Un approccio diverso alla costruzione delle tavole basato su un approfondito studio del core(anima), della tavola.

Speriamo di poterne provare presto una.

thirst snowboards

The core of a snowboard is the main and the ultimate component. It is what determines flex, stiffness and durability. I have not found a single company that has taken advantage of truly engineering the core of a snowboard. I have been developing and building snowboards with a different construction concept since 1980.

Every snowboard manufacturer does one thing with the piece of laminated wood that is sliced from a core block. They profile it in a jig called a crib. This profiling of the parabolic sweep gives the board the difference in thickness from tip to waist to tail. It is still one piece sliced from the core block. Then the additional materials are added to the top and bottom of this profiled blank.

Thirst snowboards does NOT follow this antiquated construction technique.

All core block materials are hand selected and made in-house. The core blanks that are used are book-matched to provide the most perfectly matched materails in post blank assembly.

All my cores are designed with a PFI (parabolic flex insert). PFI's are of two basic designs:

HQI: Herringbone quasi-isotropic. A construction type that offers the ability to fine tune flex for tip and/or tail.

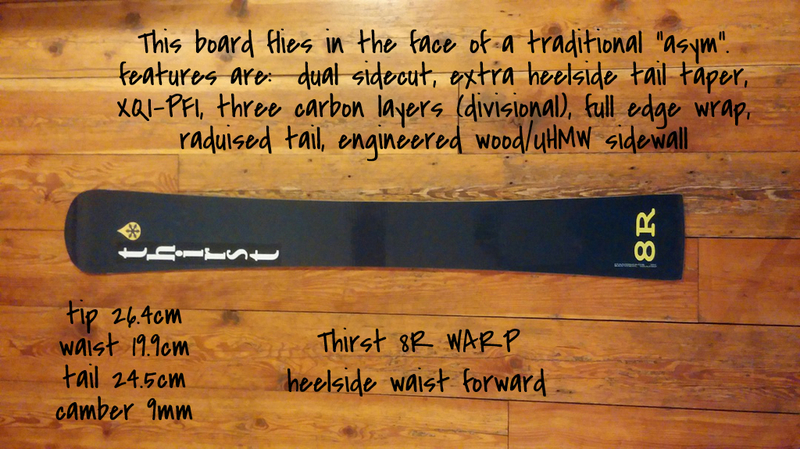

XQI: "X" style quasi-isotropic. A construction type that provides an excellent overall flex character, a preference for longer boards over 180cm.

PFI is an important component that can be tuned by its construction to provide torsional stiffness and flex in a manner other than a thicker core for a stiffer board.

Thirst boards are engineered with 35+ components—not counting core blank/blanks and insert packs.

We build for strength as well as proper flex.

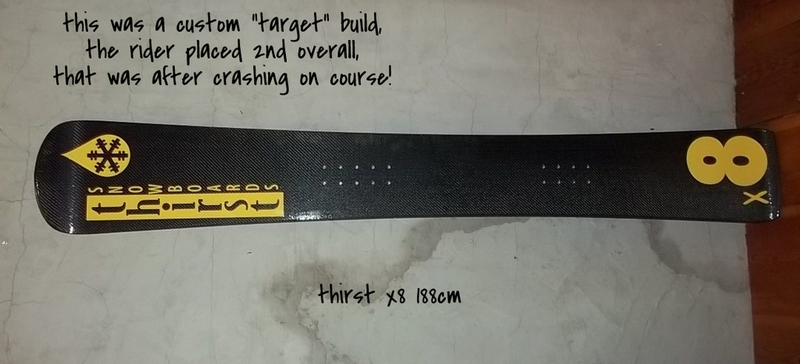

Thirst Snowboards offer a refinement unavailable anywhere else. The core of your board will be tuned to your weight and your style of alpine riding. It won’t be retrieved from a computer, or built from a cookie cutter pattern. I make one board at a time for the person that ordered it.

The side-cut design is not an industry standard radius or radius blend.

Thirst Snowboards side-cut curve is called EX-EL.

The side-cut cannot be defined as a true radius arc, is more refined than a blended arc and is designed to work with the flex dynamic of the snowboard. EX-EL side-cut provides full length effective edge contact. THIS SIDE-CUT DESIGN HAS PROVEN TO ALLOW THE STIFFNESS OF A BOARD TO BE LESS OF A CONCERN IN RIDER WEIGHT. DURING DEMO TESTING WE HAVE EXPERIENCED RIDERS COMMENTING ON HOW WELL THE BOARD HOLDS AND EDGE, IS FORGIVING AND FUN TO RIDE. THE RIDERS HAVE HAD WEIGHT DIFFERENTIALS OF MORE THAT 50LBS, NEARLY A FOOT IN HEIGHT, AND STANCE DIFFERENCES OF 4"

ALL THIRST BOARDS ARE CONSTRUCTED WITH RACE QUALITY FULL-WRAP METAL EDGES.

AN ADDITIONAL FEATURE IN SHAPE IS RC3T. RC3T IS REVERSED CAMBER TIP AND TAIL TRANSISTION. RC3T HELPS TO RELEIVE PRESSURE AT TIP AND TAIL IN OTHER THAN CARVING SITUATIONS FOR EASIER SIDE-SLIPPING. SPECIAL CARE IS TAKEN WHEN DESIGING THIS FEATURE TO ENSURE THAT FULL EDGE CONTACT IS MAINTAINED DURING EDGE SET CARVING.

I have invented a technique for measuring board stiffness. This will allow us to know how soft or stiff your board will be and to compare to another board you have. If you have a board that you like especially because of the stiffness, I will explain this simple technique so we have a measured baseline to compare from.

httpv://www.youtube.com/watch?v=6O0pUtYX3iQ

httpv://www.youtube.com/watch?v=GOOo2kI26Bs